|

|

|

|

|

|

|

Windlass and ANCHORING System |

||||

An anchoring system was designed and installed in 2007. |

||||

|

|

|

|

|

|

|

|

|

The anchor is a 22-lb stainless steel Manta

(Bruce-type). I custom-made the

bow-roller assembly from ¼” thick bronze plate and 1-1/4” thick bronze stock

to fit around the original bow casting.

Two bronze rollers are encased in the assembly. The rollers and the top plate of the

bow-roller assembly control the anchor as it is pulled into its stored

position by the windlass. The windlass is a vertical |

||

|

|

|

The original bronze

cowl vent brings fresh air into the anchor well and forward cabin. Any water that comes into the vent will

drain into the anchor well and out a new drain placed at the waterline. This drain has a directional check valve;

this prevents lake water from entering the anchor well when the bow punches

into big waves. |

||

|

|

|

The anchor-line holding well was made from 5mm

marine plywood and mahogany edge strips.

The inside was lined with two layers of polypropylene cloth set in

West System epoxy resin (like the deck and cabin top). The front piece is varnished mahogany,

matching the interior trim. Any mud or

water that comes in on the anchor line and chain is contained and discharged

through the waterline drain mentioned above.

Nothing enters the bilge. We have 25’ of 5/16” high-tensile galvanized

chain and 270’ of 5/8” 8-plait nylon anchor line. 175' is stored in the well and the additional 120' is in reserve under the V-berth.

The windlass motor is mounted under the

deck. The short vertical drop from the

deck to the bottom of the anchor well requires a second, tailing device to

pull the line and chain into the compartment.

Without this tailing motor, the line is prone to bunching in the

windlass. The tailing device has two

gear-driven rollers. Springs permit

the distance between the rollers to be automatically adjusted to match the

size of the line. This allows the

device to smoothly tail the anchor line, as well as the sections of spliced

line and anchor chain (each with different diameters). |

||

|

|

|

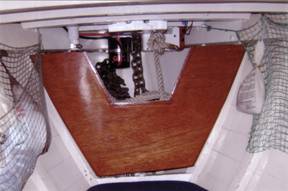

The anchor well is shown with the service

access door installed. The windlass

assembly and holding well fit within the forepeak and do not reduce the size

of the V-berth. The area on each side

of the service access door allows the cowl vent to provide fresh air to the

forward cabin. The water tank was moved from the cockpit to

underneath the V-berth. The fill

fitting is located on the deck near the bow, and the water-tank vent is above

the anchor well but inside the cabin.

This prevents deck water from entering the fresh water supply and also

prevents water-tank overflow from entering the bilge when filling the tank. |

||